Introduction

PCBGrip is a kit of mechanical components that is designed to integrate seamlessly with the framing system as OpenBeam (here to visit the official site).. Thus you can consider it as one of the kits useful for a rapid prototyping. This extension adds new features to the already enormous flexibility of the framing system, in particular, you will have a better integration of the electronic components. In fact, thanks to a series of specialized components in the gripping and clamping of cables, pins, PCB, probes, sensors, etc.. you can use this kit for many uses, including the analysis of electronic circuits or boards, soldering precise otherwise difficult, and desoldering of components from a PCB.

PCBGrip Kit and the T-slot framing system0 (OpenBeam)

PCBGrip is currently available in 4 different types of kits, each of which corresponds to a growing number of components (Kit 50, Kit 150, Kit 350 and Kit 750). Once you’ve ordered the kit, this will be delivered to your house packed in a handy multi-compartment box, along with a black metal base that you will see later what is.

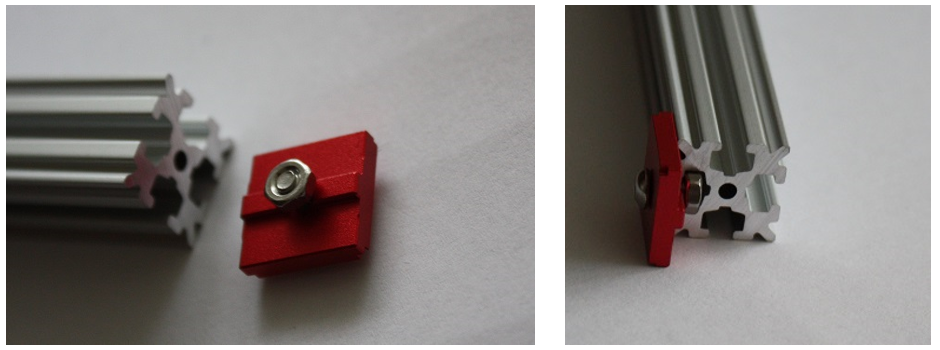

Taking a quick glance at the components contained in the box (see Figure above), you can see that there are many parts designed to be assembled together, but also well integrable to framing system as OpenBeam. In fact, all the components of the kit have holes threaded for bolts M3 (3mm) that can be well-channeled inside the grooves of the aluminum section as it wants the OpenBeam practice (but also other types of T-slot framing). (see article).

T-slot technology allows you to assemble quickly and easily, both infrastructure components such as aluminum profiles, that mechanical components such as pulleys, motors, linear bearings. In addition, you have the option to change the position of any component by sliding, without having to create new holes with a drill (often irreversible operations). If you have already worked with these aluminum sections you will certainly have noticed the many advantages, even to create simple structures as a shelf or a table.

Thus PCBGrip fits well with this technology, adding for its part, a whole new set of components, specialized for clamping, gripping, positioning of electronic components.

The PCBGrip system

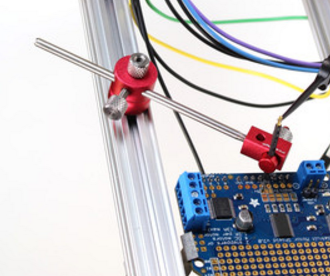

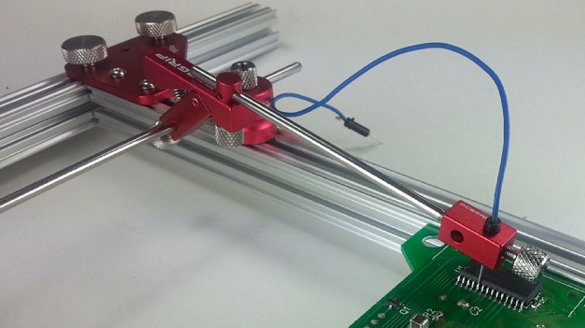

If you have some familiarity with the framing system, you can find some difficulty with using cylindrical rods and how to integrate them to OpenBeam efficiently. Well, it can be said that PCBGrip also opened the way to that. In fact, in the PCBGrip kit, many metal rods and joints (parts in red) are present. The joints allow to assemble these rods with different angles of configuration. Some joints are even adjustable and therefore allow you to rotate the rods to each other with different degrees of freedom.

Thus PCBGrip allows you to assemble mobile arms with different degrees of freedom of motion that will allow you to reach very specific points within the assembled structure. If you add a probe or a sensor at the end of these arms, this type of structure there will be extremely useful to “test” the parts contained within the structure assembled with the framing system (see Figure above).

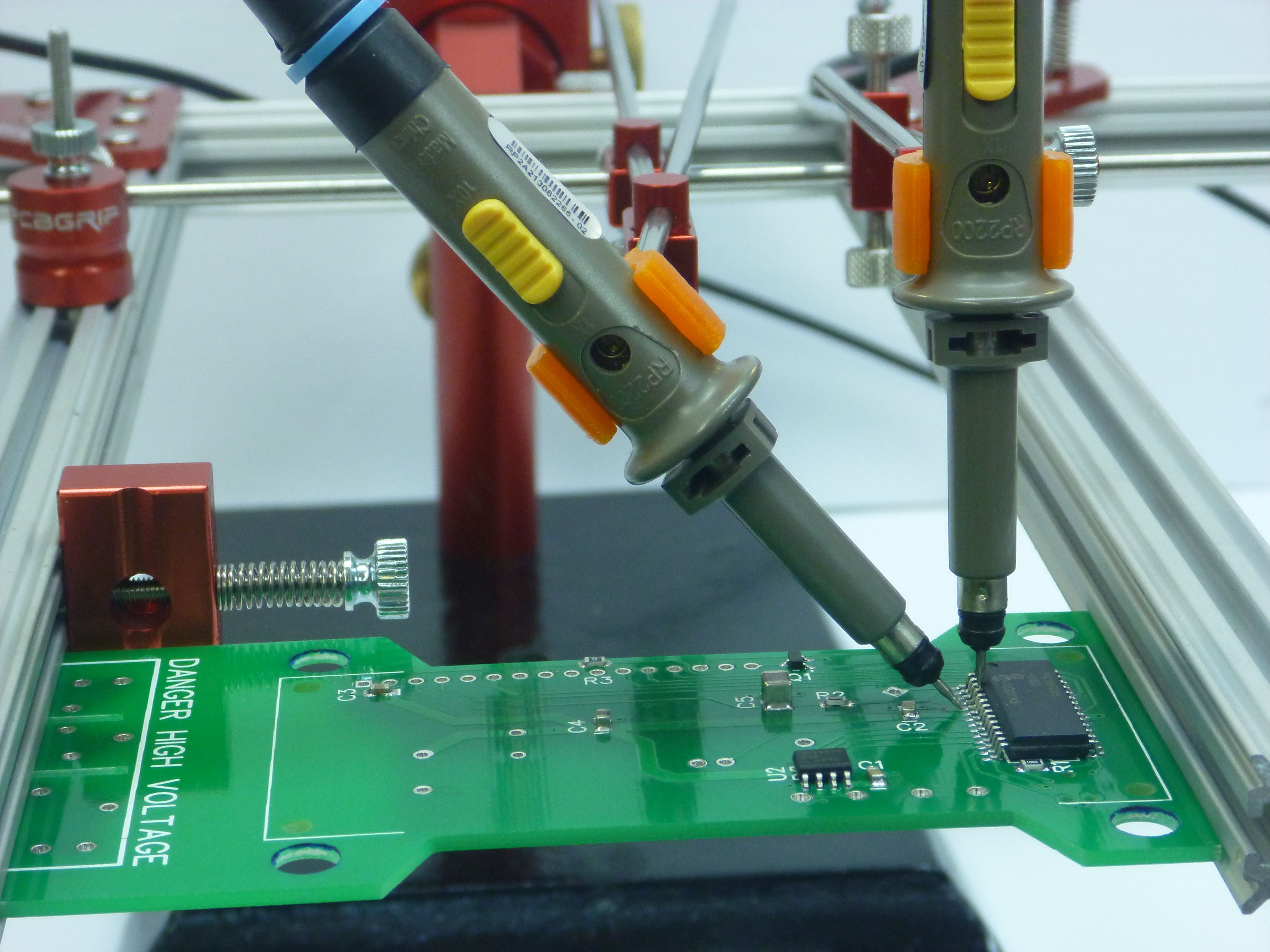

A practical case is that of an electronic circuit board PCB of which you want to analyze its operation. The components of the kit PCBGrip provide a whole series of clamps or other clamping systems (also for cables) that further facilitate this type of analysis. You can also attach the probes of an oscilloscope, an analyzer, or even a simple multimeter (see Figure below).

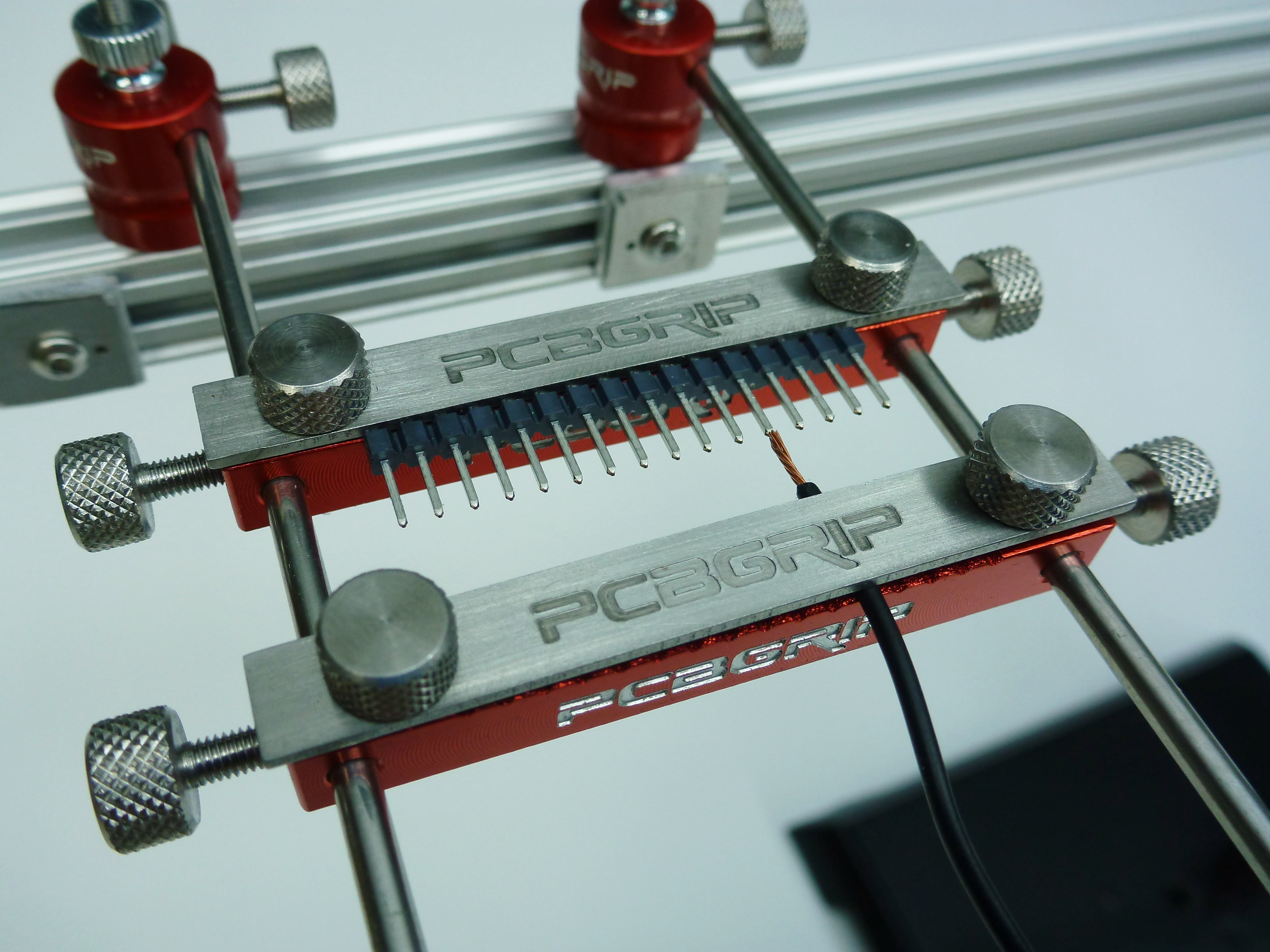

The types of clamps you can find within the kit, are numerous, such as several may be their applications. For example, another possible application of the components of the kit is for soldering. Thanks to the components in the kit, you can keep various electronic components in a precise position, precisely and firmly. This will allow you to think exclusively to solder the electronic components without worrying about holding them. In this case, for example, you may need a type of clamp that allows you to hold a large number of cables in parallel, while you are trying to align them with the pins of a connector; all this, maintaining the cables well separate between them (see Figure below)

The adaptability of the PCBGrip kit

The examples that you just saw are only a small part of what you can actually achieve with this kit. In fact, the examples we have seen previously are just assemblies of smaller components, the real bricks of the kit. So it is the skill and imagination of those who use it to find all kinds of applications.

Here it is another example of the probe (see figure below)

As you have read in the introduction, along with the box multi compartments, the PCBGrip kit also includes a metal base. This is provided inside the kit to create “tabletop” assemblies. This metal base, combined with other components in the kit, allows you to take advantage of all the capabilities of PCBGrip as a tabletop device useful in any electronics laboratory (and not only).

Thus, PCBGrip is not only suitable for framing systems such as OpenBeam, but allows you to use it in other contexts. There is much online material about the use of this kit. As for my part, I find some videos on YouTube very useful. These video tutorials show simply some ideas on how to use both the base and the kit.

For example, the following video shows the possibility of desoldering electronic components from a PCB in an easy way.

In another example, the video below shows how to use the kit for the soldering of SMT circuits. The idea of creating a hinge between planes assembled with T-slot framing system is brilliant. The upper plane can be lifted and leaned back on as a lid.

Conclusions

Based on my experience, I recommend to all the makers and hobbyists to make use of the T-slot framing system (and not only to create and design 3D printers!) in order to realize many of your projects. The possibility of being able to build, test and remove your prototypes, in a totally reversible way, makes it a bit brilliant, although you like to call it simply rapid prototyping.

In other articles you saw as the integration of 3D printed parts can further enhance the modularity of this system. Generally, the electronic part of these assemblies is undervalued a bit, and then the fact that PCBGrip opens the way for further building block components, can only make us cheer.