Introduction

Every day you read articles about 3D printing and large innovations derived from it. There are countless applications that this sector offers and new goals are exceeded every month. Successes were recently considered unthinkable before, then become topics for new posts. Recently there is a new development that’s taking place in the world of 3D printing, 4D printing and programmable materials.

4D Printing is conceived and developed by the researcher Skylar Tibbits, of the Massachusetts Institute of Technology Department of Architecture (MIT). It is a new concept of 3D printing, in which the objects produced by the ordinary 3D printer, are able to self-assemble to form new structures.

The 4D Printing

In the history you can find similar ideas. In fact, in 1788, Joseph-Lousie Lagrange explained in his work, Mécanique analytique, how mechanics can be interpreted as operating in four dimensions, three spatial and one temporal. The 4D printing concept is based precisely on this concept. The objects generated by the 3D printer are not yet fully “expressed”. Only after a certain event or response these objects will be able to modify themselves in an autonomous way.

Put simply, the 4D printing aims to create objects that have not yet taken the final form at the time of printing. In particular, the printed object will take a form which may differ from time to time, according to particular conditions or external stimulation, adapting to them. Born here the concept of programmable materials.

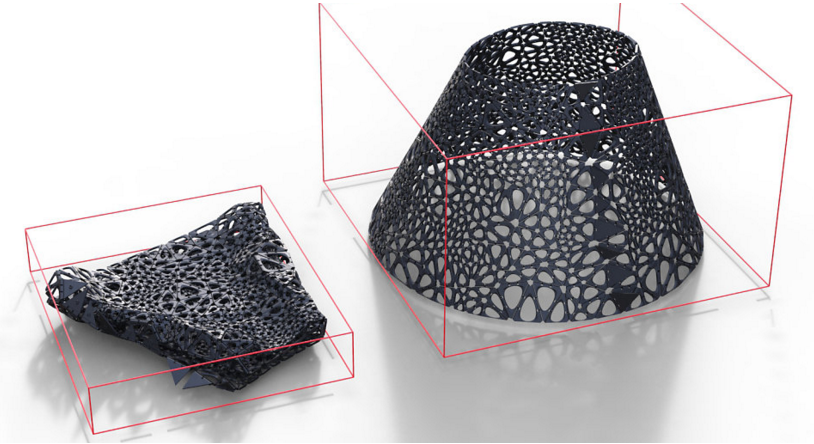

In fact, the concept of 4D printing can be achieved using many materials that change their shape in contact with the water. Once these models have been printed, generally they assume a 2D structure, simple in their geometry. Only after a certain event you will see them change, assuming very complex form, with new spectacular three-dimensional geometries.

For example, after printing you get this simple 2D hexagonal structure.

.

and then you can immerse it in water, to obtain an entirely new three-dimensional shape that slowly closes in on itself.

The dynamics of this 4D printing is visible in the following video.

A recent glaring example (January 25, 2016) is the project developed by a team at the Wyss Institute in collaboration with the Harvard School of Engineering and Applied Science. This team has developed a 4D printing method that uses a hydrogel composite structure that changes shape when immersed in water (see article here ). More precisely, they have reproduced in their experiments, the tissue composition and microstructure present in the flowers and plants. Their purpose is to study and reproduce the morphological dynamics of these natural microstructures that modify themselves according to environmental responses.

Applications

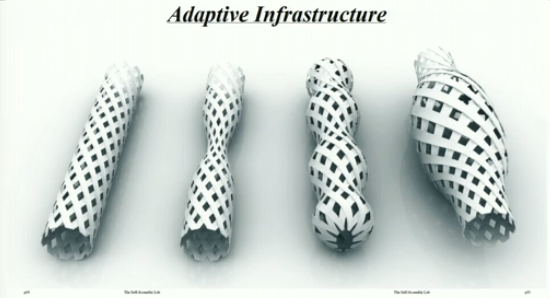

Potential applications of 4D releases are numerous. In fact, an example, could be the case of pipes able to expand or shrink depending on the volume of water which passes through them. There are currently of studies on this subject.

An application that is already taking its spaces, is to make clothes or jewelry which are able to adapt to the shape of the body. A widely used software for this purpose is Kinematics of the Nervous System (see here). This software allows you to design and print jewelry and clothing that use 4D printing. In this case you use small tiles (like a mosaic) of different shapes, each one connected to the adjacent by means of hinges. These tiles will have all different shapes and densities in order to create aesthetic and dynamic effects which differ depending on the part of the body on which they are in contact.

One of the main features of the Kinematics software is that it can simulate the “folding” of a garment or a jewel, so it can be printed even if the print sizes are too small to allow it.

Another case may be that of the realization of prosthesis can be modeled and adapted to the parts of the body or to the requests needs.

Conclusions

I assume that the press 4D will give us huge surprises in the coming years. The concept is highly innovative and still unknown to many. I hope this article will awaken in you new ideas and new applications.