Introduction

Fresh from Maker Faire 2016, with ups and downs, I came across the pavilion of the DWS where the company was presented in the new framework Factory 4.0 (or Industry 4,0 in a broader sense). But what is Industry 4.0? Let’s find out in this article.

Industry 4.0

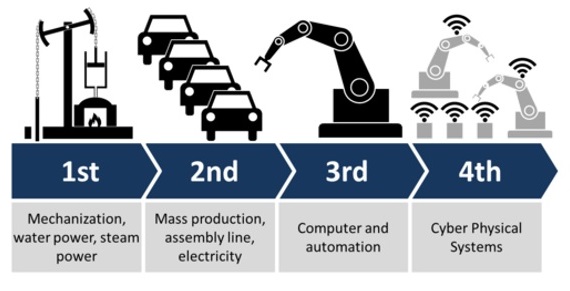

This term, Industry 4.0 indicates the fourth industrial revolution, and the way in which it is reported, as a new release of software, does understand how information technology will come more and more in this area.

The term Industry 4.0 was first used in 2011 in Germany, at the Hannover Fair. It can briefly describe it as an industrial process in which all the production step will be highly automated and interconnected. But they are still like that, or no?

No, certainly not at these levels. Technologies such as IoT (Internet of Things), Big Data, Cloud and eCommerce on Web / SmartPhone will be the new protagonists and will play a key role in these new production processes. Those familiar with these technologies can well understand that the information and data will be managed in a fully automated manner and in a much more effcient way.

In fact studies have estimated that in reality so far industries have exploited the information available on the market in a truly negligible. With the introduction of this information in the production process it will increase their use. Information is becoming the product of Industry 4.0. The data produced can become goods themselves. In fact, in production processes many new step will remain exclusively in the virtual world circle, being composed of data, files and information of various kinds, but they still have to abide by the rules of production, like any other commercial product.

But it does not end there. Specifically referring to the term Factory 4.0, it is the new production approach from virtual product conversion (ie data) to the actual product.

Factory 4.0

In fact, it needless to say that people do not live by only information, but also by real products. And it is here that the Industry 4.0 takes the most innovative and unexpected form.

In fact, as mentioned before, Factory 4.0 is the new method of converting the digital product to the actual product, say “solid, physical”.

To better understand this new concept, you can think, for example, to your 3D printer you have at home. You have an STL file (digital) of a 3D model of an object you want to achieve, and maybe you bought on the internet. Now through a 3D printer, create the real object. Nothing prevents you to be able to sell in your turn.

Now, you can think at production level. Think of digital data describing a car, a dress, an electronic device. Choose your product through an application on smartphones. For example you want a car to a certain pattern, with red paint, with a certain displacement, etc. etc. Selections that you can do with a classic drop-down menu.

You’re actually selecting the parameters of a digital file on a server located on Factory 4.0. By purchasing this item, the Factory 4.0 will start printing immediately all the components and then assemble them according to your parameters. Once completed you will be sent the car.

This is revolutionary. For example, the first thing that comes to mind is that it will be produced as many objects as requested. This reduces waste production.

It will also be produced objects when required. Then they will disappear (or at least greatly reduce) the storage time and storage costs.

Of course this was just an example to understand the concept.

Factory 4.0 – DWS a concrete example.

If you want to know a concrete example, in Italy the DWS (Digital Wax Systems) sis approaching its own to a level of production – Factory 4.0. The DWS is an Italian reality and was founded in 2007 in Vicenza.

Listen to the interview with Maurizio Costabeber, CEO of DWS who will talk about how it is applied the concept of Factory 4.0 in his company.

In addition, the DWS is seeking new young and qualified personnel who can contribute to the development of this company. Here is the brochure.

Conclusions

Of course not everything can be printable. But this is the new approach to production that soon we will all get used. Many sectors can already be adapted to this concept and go to a new level just a few months ago were unthinkable. Areas such as additive manufacturing, 3D printing, robotics, communications, machine-to-machine interactions and new technologies to store and use energy in a targeted way, will gradually more and more innovating, streamlining costs production.[:]